Researched uses for Endgrain

The initial phase of the project concentrated on single endgrain tiles for interior flooring. Through working with the material we gained a better understanding of the inherent qualities of using wood in this format. In addition from the enquiries that came from specifiers it became apparent that there was a wider potential for developing the endgrain tile into other products and markets. A series of small research projects and trials were conducted to better understand the commercial potential of some of these and to make the findings available to interested manufacturers.

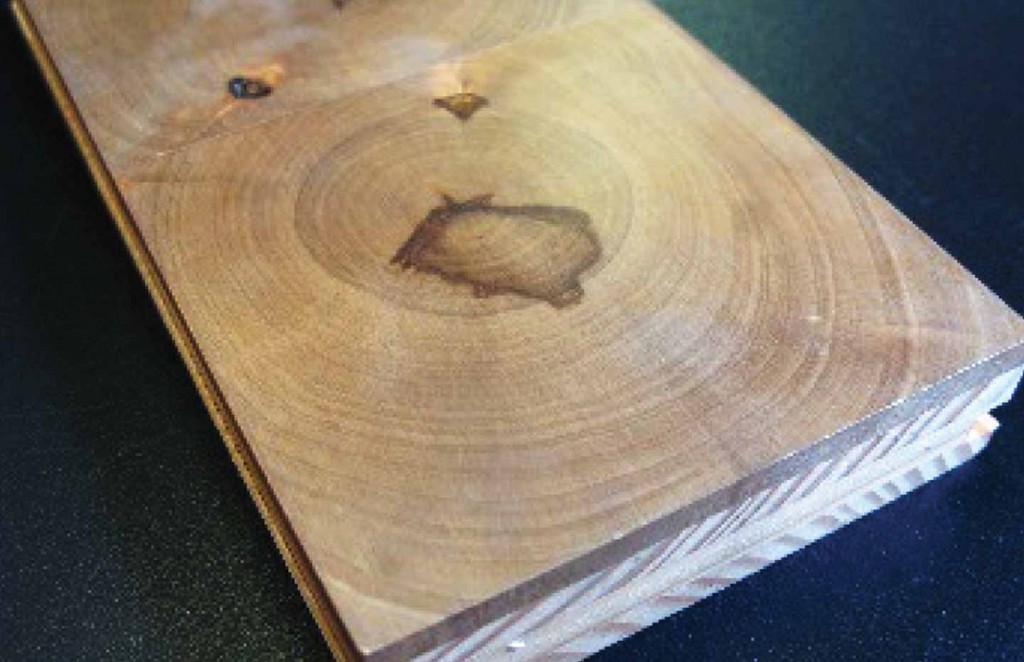

- Engineered endgrain flooring – A 4mm to 6mm wear layer was bonded onto a backing board of plywood or cross laminated softwood. This creates a stable flooring product that can be laid in the same way as conventional T&G floor board. It is easy to install and ideal for buildings with underfloor heating.

www.kentonjones.com

www.timbersource.co.uk

www.jamesratfordbridge.co.uk

www.wlwest.co.uk

- Cobbles for external and industrial use – This derives from the original use for endgrain cobbles where by thicker sections of timber are laid in areas requiring a robust surface capable of dealing with continual impact and wear. A number of enquiries to the supply chain project resulted in completed contracts for endgrain cobbles in external and industrial applications. These can be viewed under the Portfolio title. We undertook testing to look at the feasibility of adding slip resistance in wet conditions through scorching; adding durability through resin treatment; hardness and wear resistance. These can be viewed under the Research page. For potential manufacturers contact:

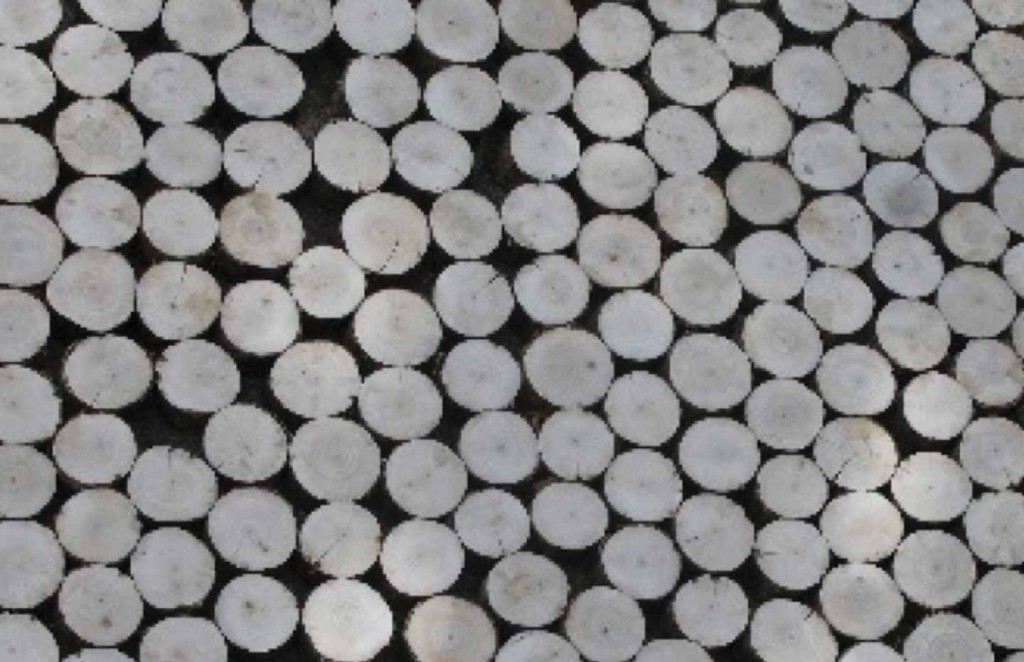

- Sound absorption wall panel – Research was conducted by Salford University to investigate the potential sound absorption properties of some of the porous timber species. Beech and poplar had surprisingly good results and both species are currently under-utilised in added value markets. The potential is to create good sound absorbing panels that are visually interesting. Feature walls out of small diameter logs have been in vogue for a few years now and this research could add a functional aspect to what is currently a highly aesthetical product. There are no manufacturers of this product. Please read the summary of the report on the Research page and contact Coed Cymru if you require any further information.

- Ovalgrain board – Small diameter logs are cut at an acute angle which produce a short board of around 300mm to 450mm in length. The length of the board means that no special jigs are necessary when machining and it can be put through most planers or moulders. The face of the board exposes the endgrain which radiates out in an oval shape from the pith. The surface is not as hard and wear resistant as endgrain tiles cut at 90 degrees to the grain, but better than a standard side-grain board. The ovalgrain board makes an attractive and distinctive flooring or wall covering. For potential manufacturers contact:

www.sandersonsfinefurniture.co.uk

www.wlwest.co.uk

- Woodcrete tiles – Waste timber chip from the manufacture of endgrain tiles or other Welsh timber products are mixed with cement. This can be poured into moulds as with conventional concrete to make floor tiles or other products. This was laid and tested in the new Coed Cymru pavilion at the Royal Welsh show ground in Builth Wells in July 2015. This makes use of and increases the potential to add value to residue material from timber production that would otherwise be dumped or burnt. The manufacturer of Woodcrete is Specialist Precast Products (SPP) in Caerphilly www.specialistprecastproducts.co.uk